I’ve always wanted a sparkfun third hand kit, so I bought one on Cyber Monday:

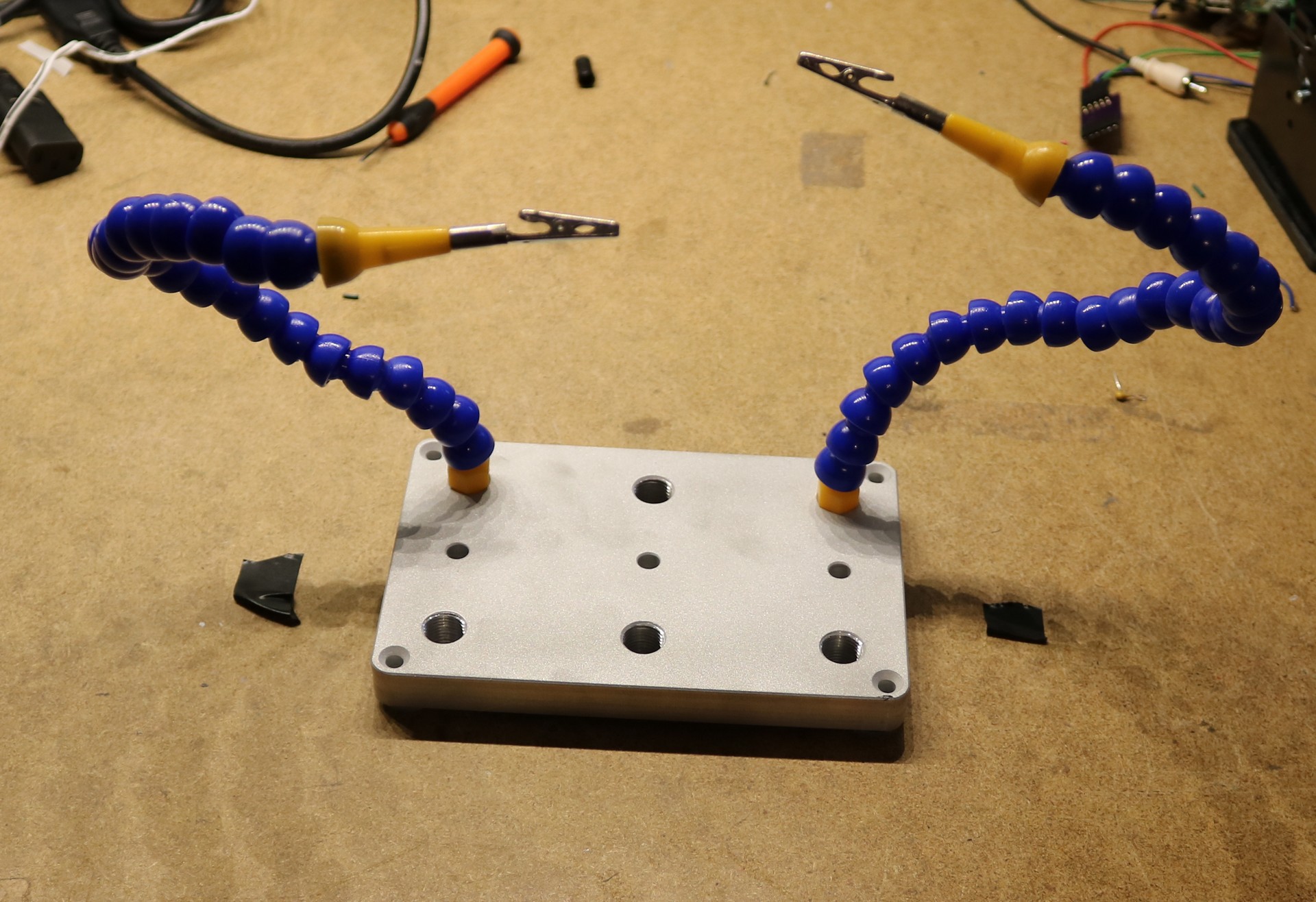

Here’s a still shot of the third hand kit as assembled:

The first thing you’ll notice is that the alligator clips are really small, as compared to my old Radio Shack Third Hand kit. I do a pretty good job of showing the relative size comparison in the video. Bigger clips would have been nicer. My other criticism is that I find the alligator clips don’t rotate all that well. One of the nice things about the old Radio Shack Third Hand is that the clips would rotate smoothly and the joints would pivot smoothly.

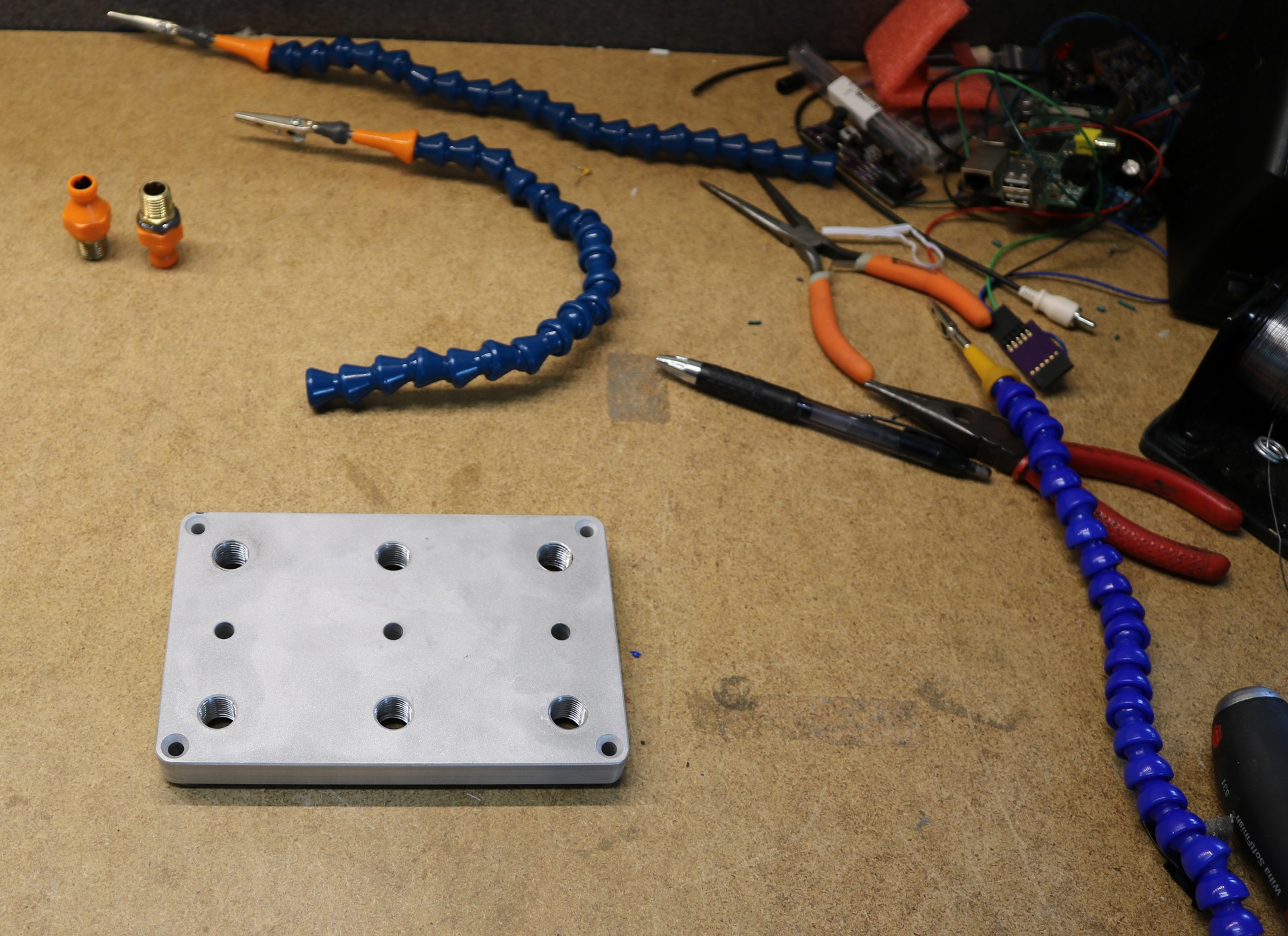

The base plate is really well done, a total of six threaded spots for attaching the flex arms (you can buy additional flex tube kits from Sparkfun). There’s also countersunk holes for screwing it down to your workbench if you wish to do so.

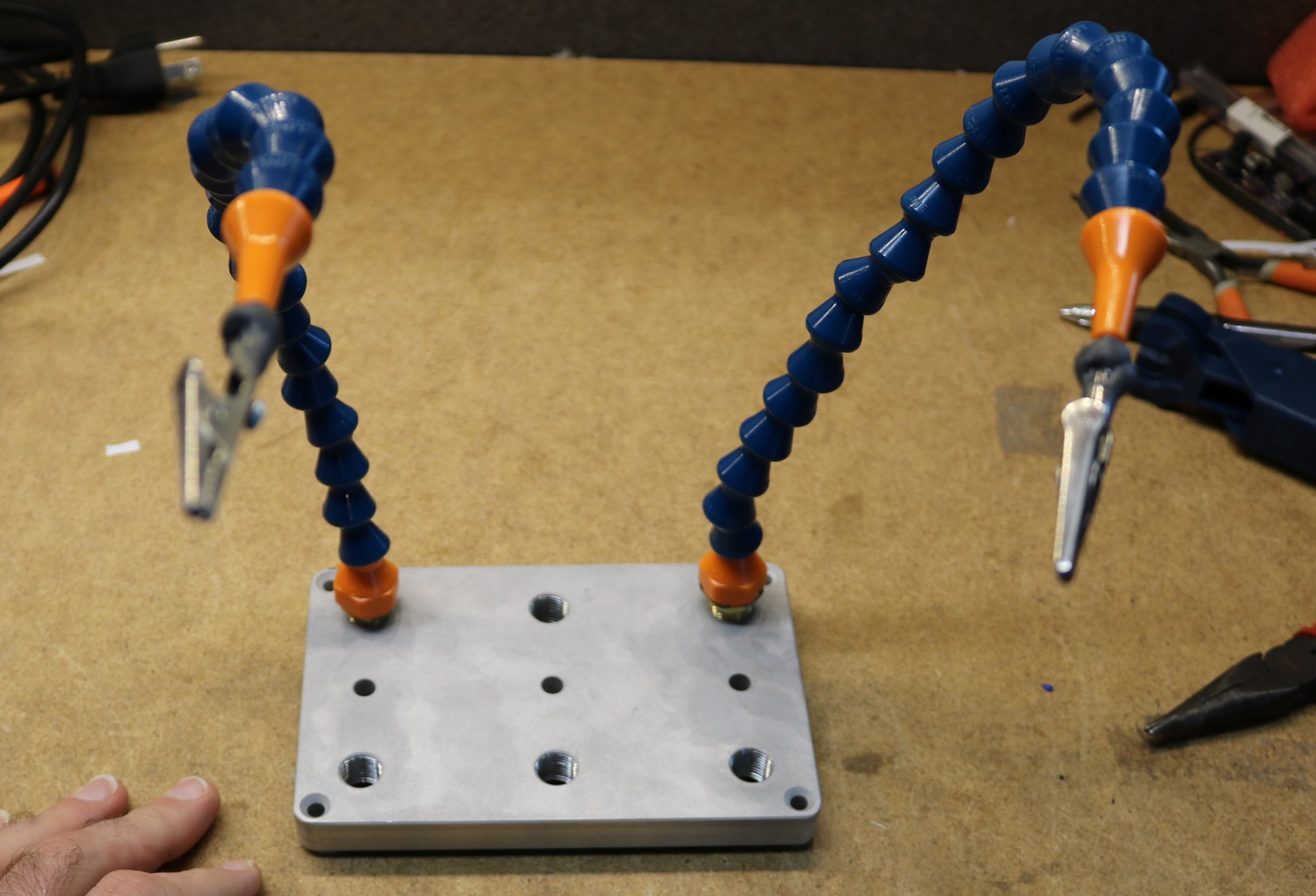

The flex tubes are what people in the machine industry would often call “Loc-Line”, though Loc-Line is a particular brand name. The stuff used in the spark fun kit is a different brand. The balls and sockets are a slightly different size than name brand Loc-Line, and are not quite compatible. I had some Loc-Line on hand, so I compared the two. I felt that the Loc-Line may have a little smother pivot action. Also of note is that the name-brand Loc-Line is a darker shade of blue than the tubes that came with the Sparkfun kit:

Since I had some name-brand Loc-Line on hand, I decided to make two new flex arms using the name brand Loc-Line and larger alligator clips. To attach my alligator clips, I JB-Welded some 8/32 nylock stop nuts onto the ends of them. The nylock nuts have just the right amount of friction for smooth rotation. The holes tapped into the aluminum plate were not the 1/4 NPT that I needed to attach my Loc-Line, but were instead metric 14×1.25. The sizes were quite close and it was easy to re-tap them using a tap and die set.

My “hack” lasted about two days and then broke. It turns out JB Weld has excellent compressional strength and sheer strength, but lousy tensile strength. If you make a JB Weld butt joint, you can snap it fairly easily. The material is a lot like concrete in that respect, and one will notice that they often add concrete to rebar. So I remade my alligator clips and added some ‘rebar’ in the form of a few chunks of 24ga solid wire to the epoxy. It hasn’t snapped again.